Brewery

|

Brew Force You just name your requirement and we design your complete brewery. |

|

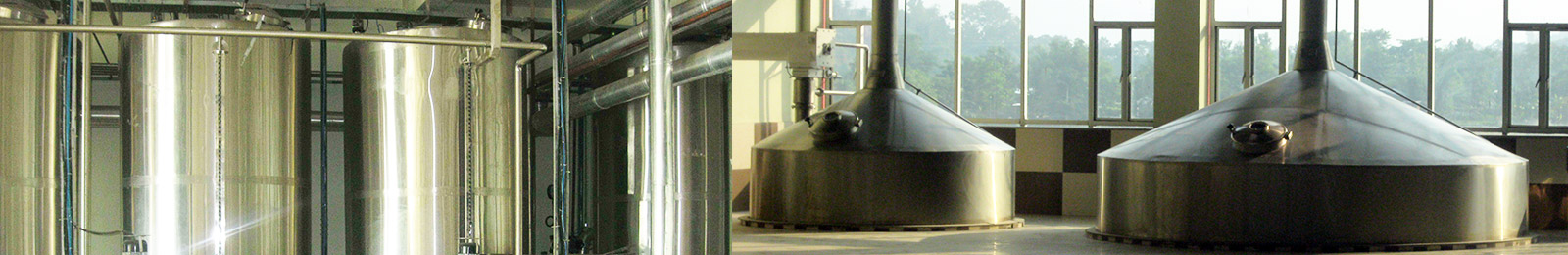

Brewery

|

|

Malt Handling Section |

|

|

Brew House |

|

Adjunct Kettle (RICE COOKER) Mash Kettle The grist is mixed with water to form a mash which is carefully

heated and agitated in the mash tun. Under controlled temperatures

the natural enzymes begin converting the insoluble starches and

proteins into a soluble malt extract known as the wort, which

contains fermentable sugars including maltose. |

|

|||||||||||||||||||||||||||||||||||||||||||||||

|

Lauter Tun The lauter tun is a large filter where the dissolved sugars of the wort are separated from the spent grain, which mainly consists of the malt husks. After lautering, the grain is sparged, or rinsed, with hot water to wash out the residual wort. |

|

|||||||||||||||||||||||||||||||||||||||||||||||

|

Wort Kettle with Internal/External Reboiler

Once the wort is separated from the husks, it is transferred to the

wort kettle to be boiled. This process develops colour and flavour.

Boiling helps extract the bitter and aroma substances from the hops,

which are introduced at this stage together with the sugar. |

|

|||||||||||||||||||||||||||||||||||||||||||||||

|

Whirlpool After boiling, the wort is transferred to the whirlpool to remove solids known as trub. This includes the hop residues and some protein material from the malt. |

|

|||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

Hygiene is probably the most important word for brewers and the hygiene should be ensured at all times! The Cleaning in Place (CIP) units enable brewers to clean all pipes, process equipment and fittings fast, hygienic and reliable.

|

|

|||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||

Utilities & Packaging |

||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||